Eddy Current Testing is a versatile Non-Destructive Testing method, which capable to detect surface defects for conductive metal even without removal of coating of that material. An electromagnetic coil is utilized to produce a magnetic field. but before discussing about this topic we must know about the basic characteristics of eddy current and how it could be produced.

Characteristics of Eddy Current

- Eddy current is current that circulate in metal conductor looks like a swirling eddies in a stream, because of this it’s known as eddy current. It acts in the vertical direction to the plane of the magnetic field and flows in closed loops within the conductor. The eddy current can be made and observed if the magnetic field surrounding a static conductor is changeable, i.e., whatever leads to the conductor changing the direction or intensity of a magnetic field may create eddy currents.

“The value of the eddy current is proportionate to the change of magnetic field and hence it’s a phenomena of changing magnetic field and frequently regarded as a secondary field.”

- Either electromagnet and permanent magnets can make an Eddy current, in addition to transformers and from the relative movement made when a magnet is situated alongside a conductive substance or plate. Eddy currents are used in particular applications, such as non-destructive testing, known as eddy current testing in NDT.

- It’s inversely proportional to the resistivity of the substance by which it generated. Therefore, many things may impact an eddy current, which also means that there are many methods by which they may be tuned.

- Eddy currents are created since a secondary magnetic field is made that opposes the first magnetic field. because of this, creation of circular field electrical area occurs. Magnetic field areas are usually represented as circular lines in which the magnetic field is directed. The electrical field lines move into a counter-clockwise path to the magnetic field lines.

- In eddy current braking, used as braking system design for the rotatable power-tool and rollercoaster, in which eddy current (The opposing magnetic fields create this resistance) have been exploited in that application of braking force generation.

What is eddy current testing in NDT?

Eddy Current Testing is a versatile Non-Destructive Testing method, which capable to detect surface defects for conductive metal even without removal of coating of that material. An electromagnetic coil is utilized to produce a magnetic field.

The most common industrial applications are in NDT-Non destructive testing purposes and in the applications that use electromagnetic damping principles.

Research Training Group Lorentz Force Velocimetry and Lorentz Force Eddy Current Testing, LET, CC BY-SA 3.0

Eddy currents in Non-Destructive Testing (NDT)

- The eddy currents may be used to discover flaws (Crack or slit) or defective parts in materials. This can be known as non-destructive eddy current testing and is frequently utilized in airplanes subsystem design and testing. The magnetic field originated by the eddy currents is quantified, where an alteration in the area shows the existence of an irregularity; a flaw will minimize this eddy current, which subsequently lessens the strength of the magnetic field.

- Eddy currents are employed in a few of the most usual electromagnetic NDT approaches to determine whether a substance or surface has some discontinuities, defects, or cracks without damaging the substance itself. NDT approaches are used extensively throughout the construction building and civil material to examine several substances. Still, eddy currents have discovered the mostly utilized to test tubular and bar-shaped substances. But, any structural problems that are circumferentially orientated are tough to detect by this eddy current testing method as it is more complex to detect.

- Eddy current testing is a popular NDT-Non destructive testing purpose with a simple technique. Eddy current testing uses a coil to produce an electromagnetic field on the material’s surface that has to be analyzed, a sample conductive material. An eddy current, will generate on the surface of the test material in counter-clockwise to the initial current direction.

- Any discontinuities, either voids or imperfection (unless circumferential), will probably soon be picked up as the eddy current density can probably change. This can also be measurable and detectable by the significant changes. Although it’s frequently used on round substances, the coils may also be adapted to discover some horizontal substances’ difficulties. There aren’t any difficulties with specific discontinuities being imperceptible because of the geometry of this substance.

How often should eddy current testing be done?

- Eddy current testing is recommended periodically; preventative testing for all tube bundles is recommended every three years.

- Eddy Current testing results have been compared to the prior test to help determine tube deterioration rates and predict future tube life, hence the durability of piping.

Purpose of eddy current testing?

This can be utilized for

- flaw detection, material identification

- heat treatment analysis of certain metals.

- material surface coating thickness measurements etc.

Image credit : Research Training Group Lorentz Force Velocimetry and Lorentz Force Eddy Current Testing, Trans longit, CC BY-SA 3.0

The advantages of eddy current testing are:

- Sensitivity to surface defects( might detect up to 0.5 mm.)

- eddy current testing capable of measuring through numerous layers.

- capable to detect even through surface-coatings.

- Automatic- Relatively uniform components could be inspected quickly and reliably with automatic or semi-automated gear, e.g., brakes, boiler tubes, and airplanes engine discs.

- Minimum pre-cleaning is required in eddy current testing method. Only important irregular surface coatings have to be eliminated, reducing prep time.

- Mobile test equipment is quite small and light, a number of the most recent gear being a little like a videotape box and weighing over two kg.

The disadvantages of eddy current testing are:

- Vulnerable to magnetic permeability changes: Slight changes in permeability may have impacted in the eddy currents generation, particularly in ferromagnetic substances. This makes testing of welds and other ferromagnetic materials challenging; however, with contemporary digital detectors and advanced design, it can be possible to improve the accuracy.

- Only for conducting substances: The substance has to have the ability to flow the electrical current, hence conductive. This makes analyzing of fiber-reinforced plastics using eddy current testing more complicated using this.

- Not able detect defects parallel to the surface: In case a planar defect doesn’t cross or interfere with the present, then the flaw won’t be detected.

- Complicated for large regions and/or intricate geometries: Maybe not acceptable for large regions and/or intricate geometries. Large area scanning may be accomplished but requires the assistance of some kind of area scanning apparatus, typically encouraged by a computer, each of which aren’t inexpensive. The more complicated the geometry becomes, the harder it’s to distinguish flaw signals from geometry influence signs. On account of the numerous factors which influence eddy currents, cautious interpretation of signs is required to differentiate between relevant and non-relevant signals.

Which factors may impacts eddy current testing?

Multiple factors impacts in accuracy of an eddy current inspections for example

- Testing frequency

- Alignment of flaws

- Lift-off

- Surface geometry.

What is eddy current testing of tubes?

- Eddy current testing utilizes to detect defect or leaks in the metal hollow pipes.

- In that process, A small magnetic probe inserts into the tube or pipe. This probe is able to move thru the length of the detecting pipe.

- Eddy current will be produced in that probe because of magnetic induction.

- If the signal deviates from standards, then it detects the faults using this eddy current testing methods.

Can eddy current detect cracks?

Yes, the eddy current crack detection method is very sensitive to detect a minor crack. This standard technique for surface inspection is also used extensively in petrochemical and aerospace, mainly in tubing inspection and metal surface inspection. It’s one of the major application of eddy current testing.

The electromagnetic damping application:

In real-life applications, it’s a principle used on railroad brakes that assist high-speed railroad carriages in stopping at specific points, since the interaction between the eddy current and conductive substances slows the train’s movement with no necessity for bodily brakes. Another usage is in the plan of galvanometers. These devices measure small electric currents, where eddy currents may be employed to cancel the galvanometer’s deflections, so the coil used from the galvanometer reaches balance.

Who invented eddy current?

Eddy currents were observed in 1824 by scientists and Prime Minister of France, François Arago. He recognized that it had been likely to magnetize most conductor and has been the first to watch rotary magnetism.

After ten years, around 1834, Lenz’s Law was postulated by Heinrich Lenz.

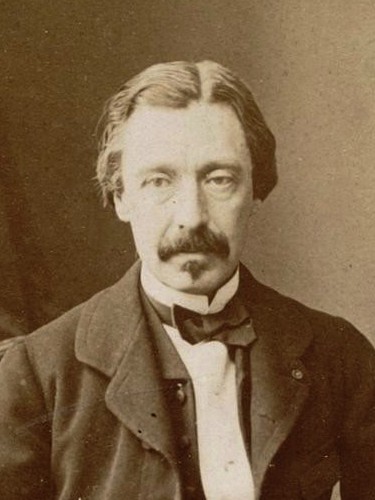

However, it was not until 1855 the French physicist Léon Foucault formally discovered eddy currents.

Image credit : Zátonyi Sándor, (ifj.) Fizped, Foucault portre crop, CC BY 3.0

What is the formula of eddy current?

The eddy current loss or (I2R) loss, can be calculated as standard where I is the value of the current and R is the resistance of the eddy current path.

Though eddy current measurement for large complex geometry is complicated and need to be calculated by elliptical integral solution and considering impedance, mutual inductance between interfering and contributing coils also.

Disadvantages of Eddy Currents:

There is a major heat loss during circulation of eddy currents due to friction in the magnetic circuit.

The disadvantages of the eddy current can be reduced by making thin strips instead of a block of the core of induction because as the blocks are made of thin strips, the no of possible loops reduces.

To know more about Eddy current click Eddy Current Brake and Eddy Current Sensor.

Also Read:

- Quotient rule

- Do eukaryotes have introns

- Is a carbohydrate a monomer or polymer

- Portable solar panels

- Detailed overview on wind tunnel

- Osmosis vs diffusion

- Tsunami the most devastating calamity

- Parallel line

- Vapour condensation

- Overdamped vs critically damped

I am Subrata, Ph.D. in Engineering, more specifically interested in Nuclear and Energy science related domains. I have multi-domain experience starting from Service Engineer for electronics drives and micro-controller to specialized R&D work. I have worked on various projects, including nuclear fission, fusion to solar photovoltaics, heater design, and other projects. I have a keen interest in the science domain, energy, electronics and instrumentation, and industrial automation, primarily because of the wide range of stimulating problems inherited to this field, and every day it’s changing with industrial demand. Our aim here is to exemplify these unconventional, complex science subjects in an easy and understandable to the point manner.

Hi Fellow Reader,

We're a small team at Techiescience, working hard among the big players. If you like what you see, please share our content on social media. Your support makes a big difference. Thank you!